Introduction

Diving into the vibrant world of custom vinyl printing opens up a realm of creative possibilities, where imagination meets precision. Whether it's crafting unique stickers, eye-catching decals, or personalized designs, having the right tools and understanding the nuances of the process can make all the difference. From selecting high-quality vinyl sheets to mastering design software, each step is crucial in bringing artistic visions to life.

As the vinyl sticker market continues to flourish, understanding the types of materials available and how to troubleshoot common challenges becomes essential for anyone looking to make their mark. This guide will walk through the must-have tools, design techniques, and practical tips to ensure that every project not only meets expectations but exceeds them.

Get ready to unleash creativity and transform ideas into stunning vinyl creations!

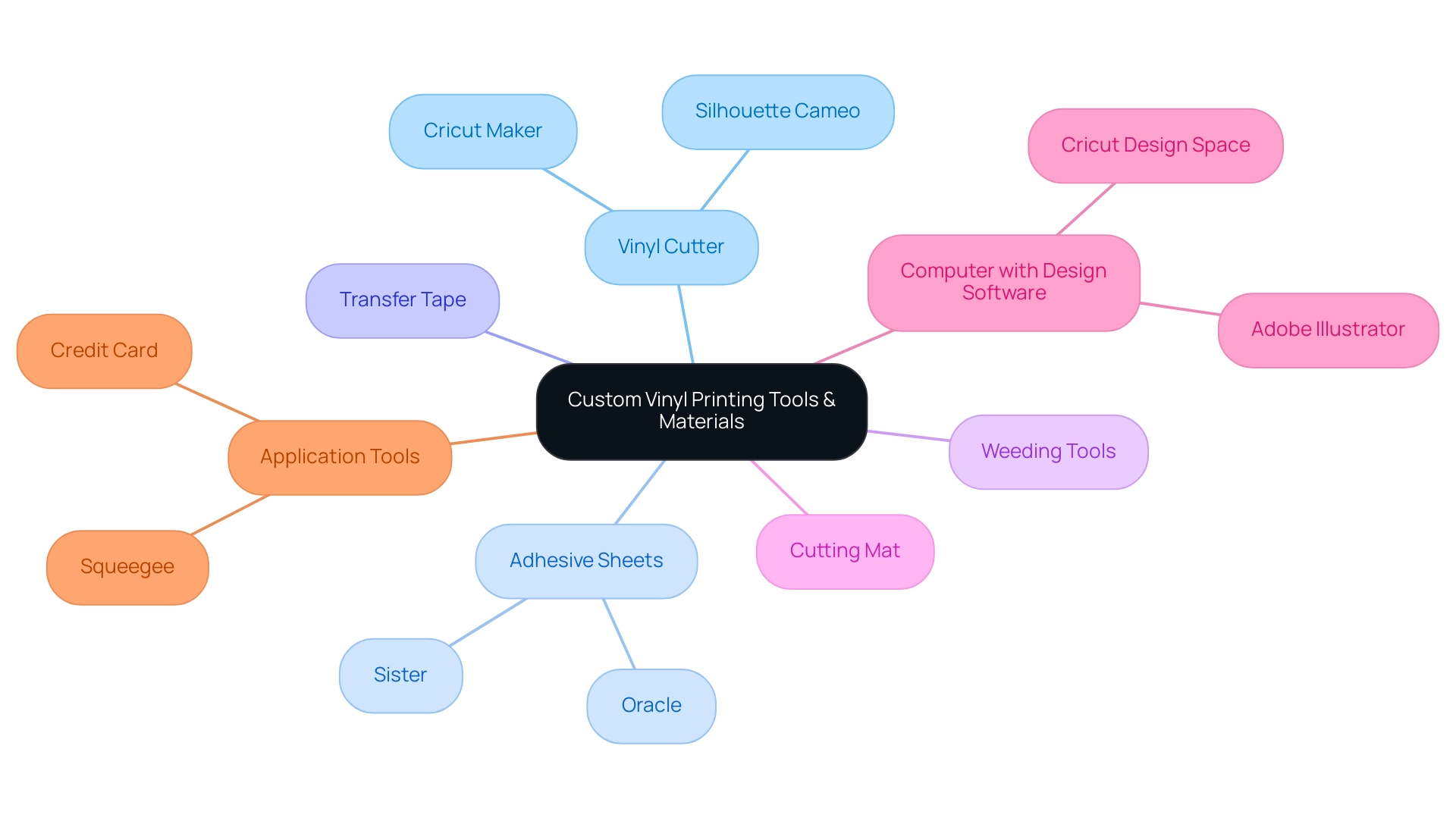

Essential Tools and Materials for Custom Vinyl Printing

Embarking on the journey of custom vinyl printing is an exciting endeavor, and having the right tools and materials for custom vinyl printing is essential to set you up for success. The process starts with producing a digital creation, whether it's a logo, artwork, or a photograph that you want to print. This layout should be prepared using graphic creation software and optimized for the specific substrate and print requirements to ensure the best results.

Here’s what you’ll need to get started:

- Vinyl Cutter: This is your reliable companion, skillfully slicing material sheets into the forms and patterns you imagine. The Cricut Maker and Silhouette Cameo are among the top choices that many enthusiasts rave about, allowing for precise cuts that match your optimized designs.

- Adhesive Sheets: Choose premium quality adhesive sheets in a spectrum of colors. Brands such as Oracle and Sister have gained respect in the community, making them trustworthy options that enhance your creations customized for different surfaces.

- Transfer Tape: This useful material assists you in moving your detailed creations onto different surfaces while maintaining everything securely, ensuring that your enhanced layout adheres properly.

- Weeding Tools: Consider these as your precision instruments for removing excess material. A basic weeding tool set will do the trick and ensure your creations look sharp and clean, particularly after optimizing for substrate compatibility.

- Cutting Mat: A sticky mat is crucial, as it holds your vinyl steady while the cutter works its magic, providing a stable base for your detailed designs.

- Computer with Design Software: You'll want software like Adobe Illustrator or Cricut Design Space to bring your creative visions to life, allowing you to create and modify with ease. This step is vital, as a well-crafted layout optimized for the substrate sets the tone for the quality of your final product.

- Application Tools: A simple squeegee or even a credit card can be your best friends here, assisting you in applying your material smoothly to avoid those pesky air bubbles, ensuring that your design transfers flawlessly.

With these essential tools and materials in hand, you’ll be well on your way to mastering the art of custom vinyl printing and unleashing your creativity. Just as mindfulness techniques enhance performance in high-stakes presentations by maintaining composure, precision in your printing process will ensure that your creative expressions are executed flawlessly. This connection underscores the importance of focus and attention to detail in both realms.

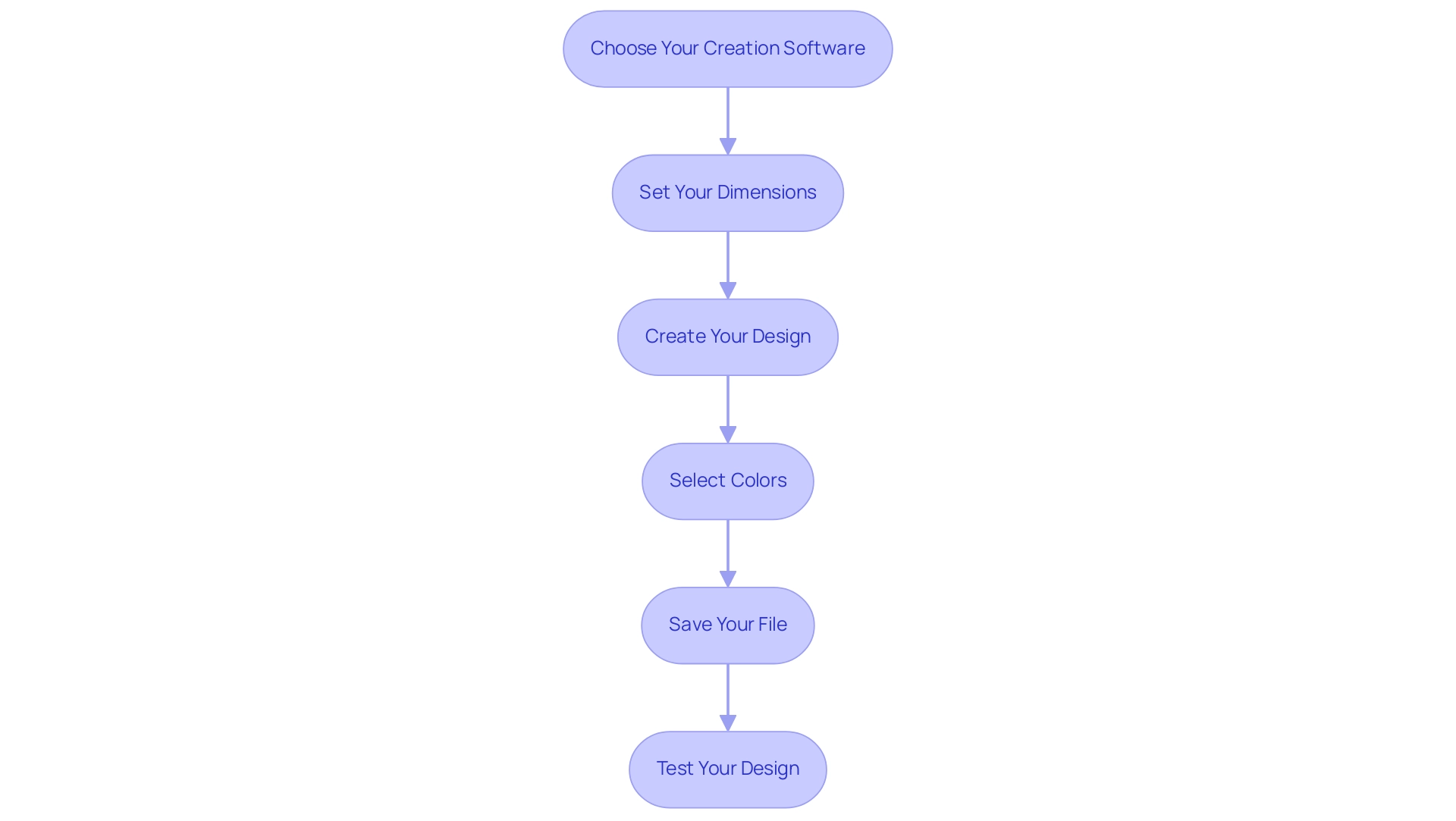

Step-by-Step Guide to Designing Your Custom Vinyl Stickers

Creating your personalized vinyl decals can be an exciting venture, especially considering that the vinyl decal market is projected to grow at a CAGR of 5.5% from 2023 to 2032. Following these steps will set you on the right path:

-

Choose Your Creation Software: Start by selecting your creation software. For beginners, user-friendly options like Canva or Cricut Design Space can make the process enjoyable and intuitive. Canva Pro, for instance, is packed with templates that can inspire creativity. It is particularly useful for creating transparent PNG files and using commercially licensed fonts, although users should verify font ownership for commercial use.

-

Set Your Dimensions: Choose the size of your label and modify the dimensions in your file. This is crucial for ensuring that your final product appears exactly as you envision it.

-

Create Your Design: Bring your sticker to life by incorporating shapes, text, and images. Aim for a creation that reflects your personal style or aligns with your brand identity. Remember, a distinctive layout can significantly enhance brand recognition.

-

Select Colors: Choose vibrant colors that complement each other and ensure they will look appealing once printed. Consider testing color combinations to find the perfect palette that resonates with your audience.

-

Save Your File: Once your creation is complete, export it in a compatible file format, such as SVG or PNG, to ensure it’s easily readable by your cutting machine. This step is essential for a smooth production process.

-

Test Your Design: Before committing to the final cut, print a test page on regular paper. This allows you to evaluate how your design looks at full size, making any necessary adjustments before the final production.

By following these steps, you’ll be well-prepared to make impressive custom vinyl printing decals that draw attention and showcase your creativity. As Sarah Dodds wisely suggests, "Let me know in the comments if you have any other recommendations as I’m sure there are lots more, or if you have any questions!" Feel free to share any additional tips or questions you may have in the comments!

Understanding Different Types of Vinyl Stickers

When exploring the realm of custom vinyl printing, understanding the subtleties of each variety can greatly enhance your project's success, particularly in light of the trends noted in the Vinyl Decal Market from 2020 to 2022. Here’s a fun yet professional breakdown of the most common types you’ll encounter:

-

Die-Cut Stickers: Imagine your logo or artwork perfectly outlined in a custom shape— that’s the magic of die-cut stickers. They’re the go-to choice for intricate designs that demand attention, making them a favorite among marketers looking to make a statement.

-

Kiss-Cut Stickers: These beauties are cut through the material but leave the backing intact, making them a breeze to peel away. If you're looking to distribute labels easily—think giveaways or mailing—kiss-cut is your best friend. They embody the perfect mix of functionality and flair.

-

Clear Stickers: Want to create a sleek, modern look? Clear labels, crafted from transparent vinyl, let the surface beneath shine through, making them perfect for a subtle yet stylish statement. They cater to the current consumer preference for minimalism.

-

Removable Labels: If flexibility is your game, removable labels are designed to peel off easily without leaving a sticky mess. They're perfect for temporary displays or changing your mind down the road, aligning with the trend of adaptable marketing strategies.

-

Permanent Labels: Designed to endure the test of time (and the elements), permanent labels are your selection for outdoor uses or any project that demands serious durability. Their reliability resonates well with marketers aiming for long-lasting impressions.

By familiarizing yourself with these types, you’ll be well-equipped to choose the custom vinyl printing option that aligns perfectly with your project goals. Remember, the appropriate label can make all the difference! And as industry leaders often say, "Choosing the right label type is as crucial as the design itself; it can elevate your brand’s visibility and impact significantly."

This insight highlights the significance of making informed choices in your sticker selections.

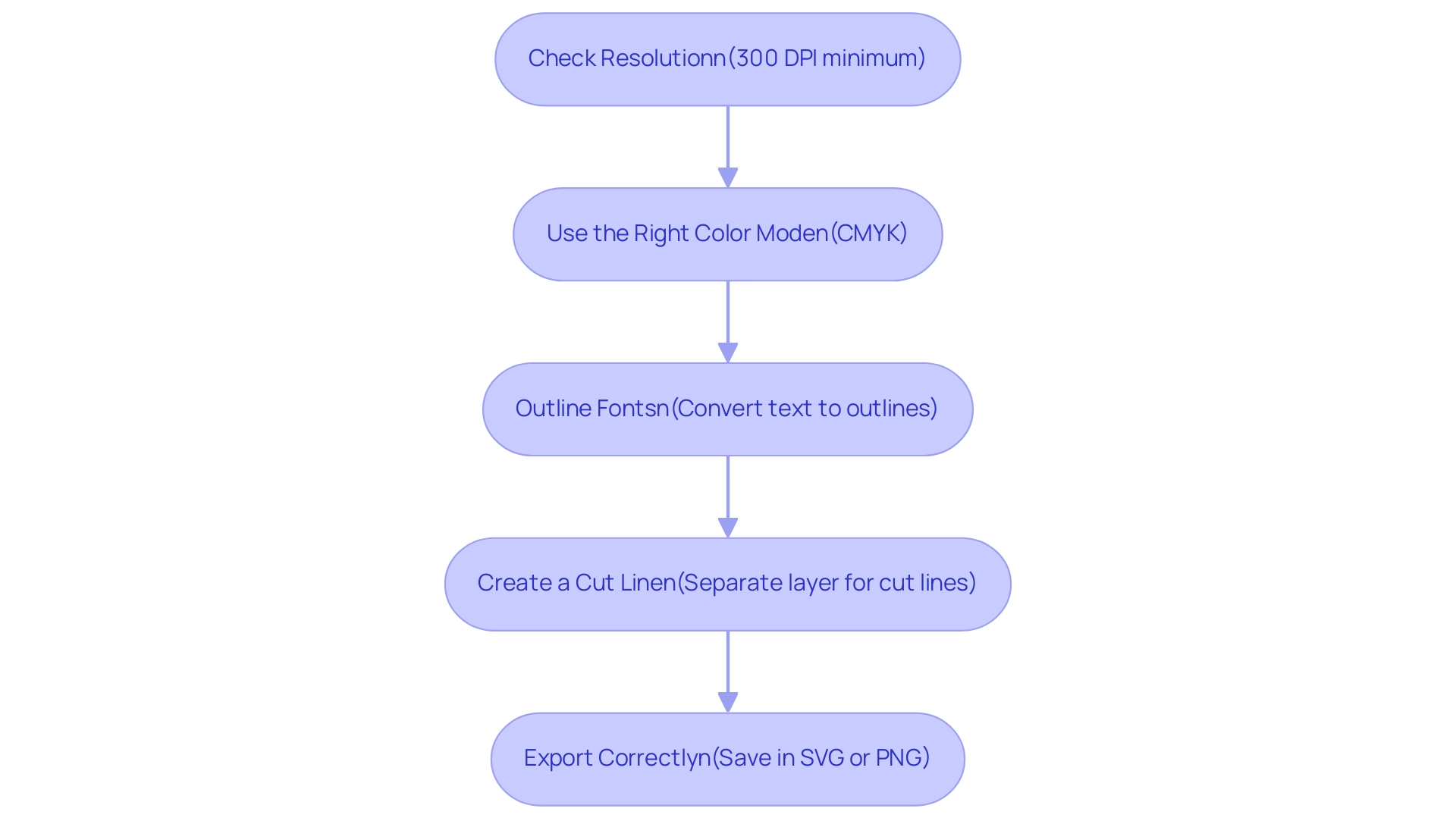

Preparing Your Files for High-Quality Vinyl Printing

Preparing your files for custom vinyl printing involves a few essential steps that can make all the difference between a mediocre print and a stunning one. Here's how to get it right:

-

Check Resolution: Aim for a resolution of at least 300 DPI (dots per inch).

This guarantees your prints are sharp and clear, capturing every detail that makes your creation stand out. For instance, posters intended for close to mid-range viewing should be printed at around 150 DPI to maintain clarity and impact. Using the correct DPI enhances their effectiveness in marketing and advertising contexts. -

Use the Right Color Mode: Make sure to set your design file to CMYK color mode.

This is the standard for producing and will help ensure that the colors you see on your screen closely match what appears on the final print. -

Outline Fonts: To avoid any potential font issues during the output, convert all text into outlines or paths.

This way, your fonts will always appear exactly as you intended, regardless of whether the printer has the same fonts installed. -

Create a Cut Line: If your project requires custom shapes, create a separate layer for cut lines.

This guides the cutter during the printing process and ensures accuracy. -

Export Correctly: Finally, save your file in a format that your cutter can read.

Formats such as SVG for vector designs or PNG for raster images are generally advised.

By adhering to these best practices, you establish the foundation for high-quality prints that utilize custom vinyl printing, ensuring they not only appear professional but also connect with your audience. Remember, as one expert aptly noted,

The only way resolution can be improved is by decreasing the image size, or by recapturing the image at a higher quality setting.

This highlights the importance of starting with the best possible image to achieve outstanding results.

Moreover, adhering to these technical specifications is crucial to avoid corrections and expedite the pressing process, ensuring that your marketing visuals effectively capture attention and drive engagement.

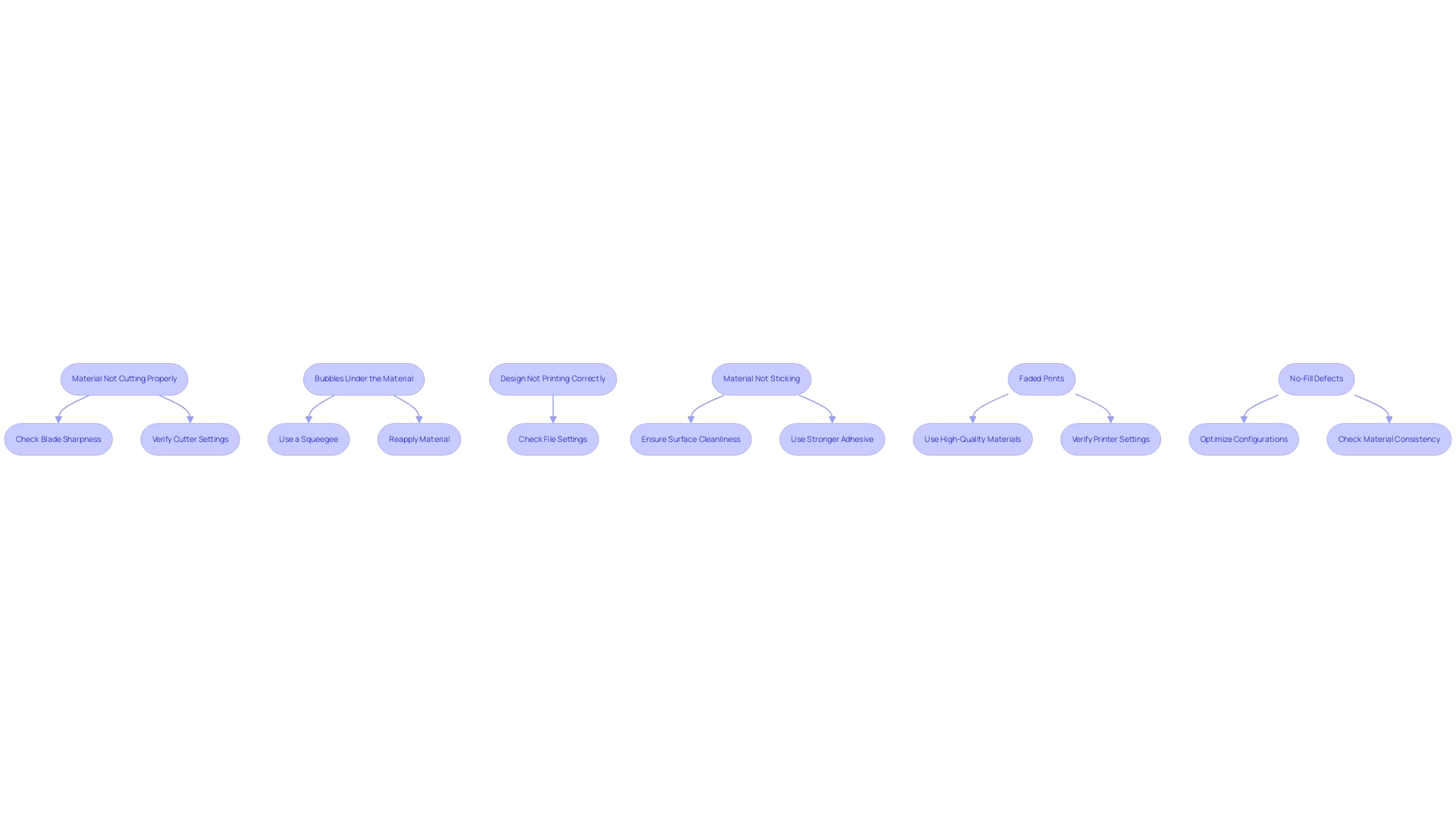

Troubleshooting Common Issues in Custom Vinyl Printing

Embarking on custom material printing can be an exciting venture, but it’s not without its challenges. Here’s a rundown of common issues you might face and how to troubleshoot them effectively:

-

Material Not Cutting Properly: If your cutter isn’t delivering precise cuts, it could be due to a dull blade or incorrect settings.

Ensure your blade is sharp and verify that the cutter's settings match the kind of material you’re using. Adjusting the pressure can also make a significant difference. -

Bubbles Under the Material: Air bubbles can be pesky when applying your film.

Use a squeegee during application to push out air pockets. If bubbles persist, don’t panic—gently lift the material and reapply it with care to ensure a smooth finish. -

Design Not Printing Correctly: A design that doesn’t print right can be frustrating.

Ensure your file settings are on point—check that the resolution and color mode are correct and that all fonts are outlined. This attention to detail can save you from costly reprints. -

Material Not Sticking: For the substance that refuses to adhere, cleanliness is crucial.

Make sure the surface is spotless and dry before applying your material. If sticking issues persist, consider using a stronger adhesive material to ensure proper application. -

Faded Prints: If your prints seem faded, this might indicate improper color settings or the use of low-quality material.

Always opt for high-quality materials and verify your printer’s settings to achieve vibrant results. -

No-Fill Defects: A common issue faced by users, no-fill defects can lead to dissatisfaction with your printed products.

Ensure that your configurations are optimized to avoid these problems, and always check your material for consistency before producing.

Being aware of these common issues and their solutions empowers you to tackle any challenges that may arise during your custom vinyl printing projects. As noted by industry expert Eddie, understanding the nuances of your materials is key:

I think we have to make a distinction between pressing faults that affect playability and those that are just cosmetic and not audible.

This perspective is invaluable in ensuring that you not only produce beautiful designs but also maintain high standards throughout your printing process.

Moreover, the case of Englishbob highlights the importance of quality control, as he shared his experience of receiving multiple copies of Plaid's 'Reachy Prints' album before finding one that was playable.

Such real-world examples serve as a reminder of the diligence needed in record production, where issues like warping can impact the final product.

Finally, it’s essential to remember that this material can last for decades if properly cared for, making it crucial to address these common issues to ensure the longevity of your prints. Furthermore, although streaming music is frequently viewed as more environmentally friendly, it depends significantly on fossil fuel-powered servers, which brings up concerns regarding the ecological effects of both analog and digital formats. By leveraging these insights and solutions, you can enhance your troubleshooting skills and elevate your efforts in custom vinyl printing.

Conclusion

Embarking on the journey of custom vinyl printing is not only about creativity but also about mastering the tools and techniques that bring designs to life. From selecting high-quality vinyl sheets and ensuring your designs are optimized for printing, to understanding the different types of stickers available, each step plays a vital role in achieving stunning results. Familiarizing oneself with essential tools like vinyl cutters and transfer tape, as well as troubleshooting common challenges, empowers creators to produce professional-grade products that stand out.

The success of custom vinyl printing lies in the details—whether it’s ensuring the right resolution for sharp prints or choosing the appropriate vinyl type for specific applications. Each choice made during the design and production process can significantly impact the final outcome, reinforcing the importance of informed decision-making. As the vinyl sticker market continues to grow, embracing these best practices will not only enhance the quality of individual projects but also contribute to a broader appreciation for the art of vinyl printing.

Ultimately, the world of custom vinyl printing is a canvas waiting to be filled with creativity and innovation. With the right knowledge and tools at hand, anyone can transform their ideas into eye-catching designs that resonate with their audience. So, dive in, experiment, and let your imagination run wild—because the possibilities in custom vinyl printing are as limitless as your creativity.