Introduction

In the dynamic world of custom printing, Direct-to-Film (DTF) transfers are emerging as a transformative force, captivating the attention of businesses and creators alike. This innovative technology is not just about applying designs; it’s about unleashing creativity with vibrant colors and intricate details on a variety of fabrics, from t-shirts to bags.

As the demand for personalized products surges, understanding the nuances of DTF transfers becomes essential for those looking to thrive in a competitive market. With the ability to quickly adapt to customer preferences and the promise of faster turnaround times, DTF is reshaping how small businesses and independent creators approach their product offerings.

Whether exploring the best providers or delving into future trends, this article will guide readers through the exciting landscape of DTF printing, illuminating its potential to elevate custom apparel to new heights.

Understanding Custom DTF Transfers: An Overview

Custom DTF transfers are transforming the realm of custom printing, providing a seamless method to apply high-quality, personalized visuals onto various fabrics, including t-shirts, hats, and bags. Unlike traditional methods like screen printing, custom DTF utilizes a specialized film and unique water-based inks, enabling the creation of intricate designs and vibrant colors that truly stand out. This innovation is a game-changer for small businesses and independent creators, offering remarkable flexibility and custom DTF printing capabilities to meet varied preferences.

With the quick curing times and effective processes inherent to custom DTF technology, projects can be completed in a fraction of the time compared to traditional methods, ensuring timely delivery and client satisfaction. As one pleased customer observed, 'The DTF prints enabled us to broaden our product line swiftly without compromising on quality.' Collaboration among global industry players fosters innovation and the sharing of best practices, further enhancing the effectiveness of DTF technology.

As industry expert Aditi Shivarkar points out, the versatility of custom DTF is gaining traction across various sectors. The increasing need for custom DTF products—evident in the graphic design sector holding more than 58% of the revenue share in 2023—makes it crucial for marketing managers to understand the subtleties of DTF processes. Keeping an eye on emerging trends, such as multifunctional powders and the integration of AI and IoT into printing processes, will not only enhance product offerings but also secure a competitive edge in this thriving market.

Comparative Analysis of Top DTF Transfer Providers

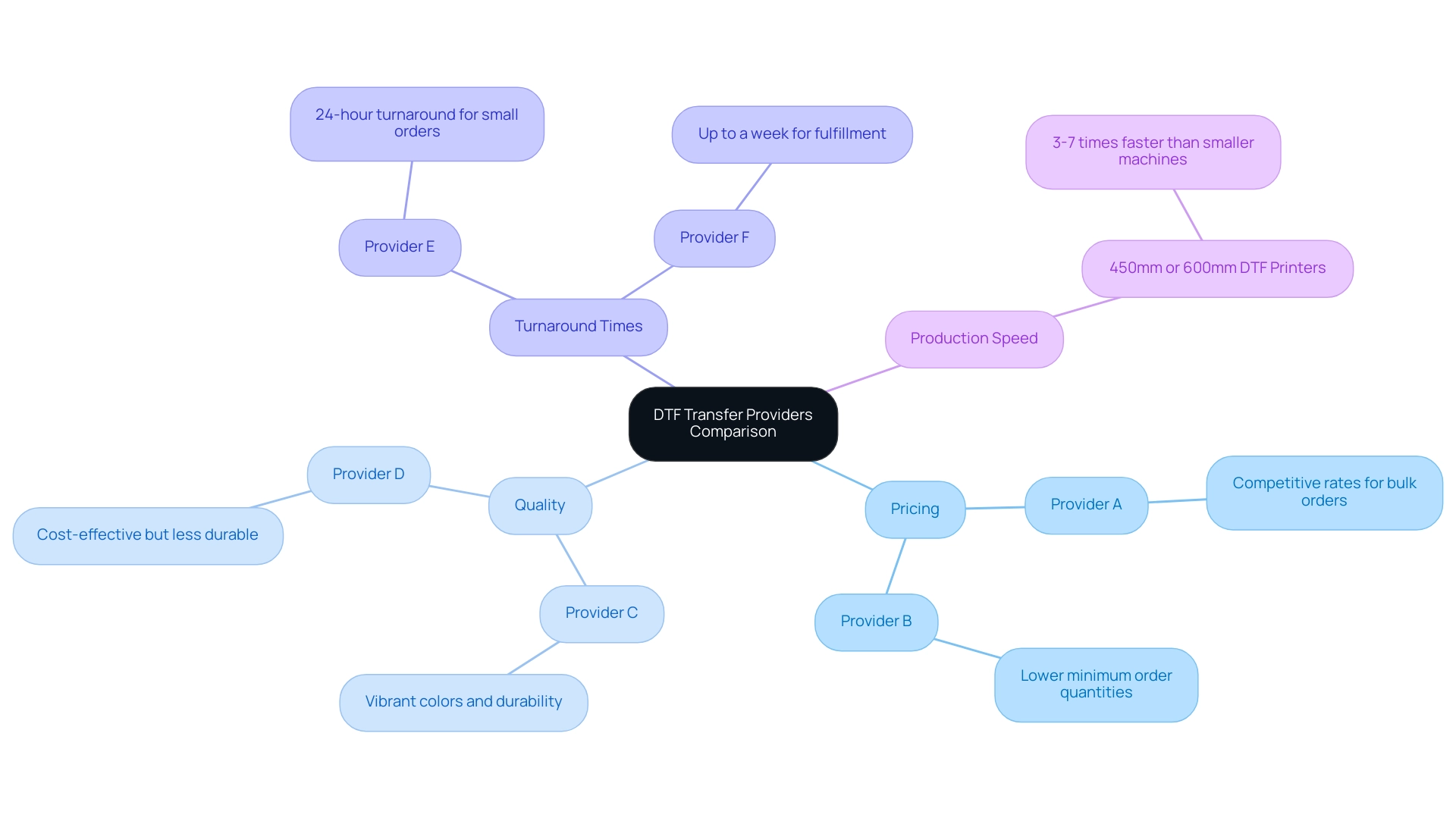

When diving into the world of DTF providers, several essential factors shape the landscape for marketing managers looking to make informed choices:

-

Pricing: In 2024, pricing strategies among providers showcase a diverse range of options. For instance, Provider A stands out with competitive rates for bulk orders, catering effectively to larger production needs. Conversely, Provider B targets small businesses and personal projects, boasting lower minimum order quantities that can be appealing for those just starting out.

-

Quality: Quality is paramount in DTF prints, and here, the differences can be stark. Provider C is celebrated for its vibrant colors and remarkable durability, ensuring that designs endure multiple washes without fading, making it a favorite among businesses prioritizing high-quality outcomes. Conversely, Provider D presents a more cost-effective option with satisfactory quality; however, users should be mindful that these transactions might not endure as well over time.

-

Turnaround Times: In today’s fast-paced market, turnaround speed plays a crucial role. Provider E excels with an impressive 24-hour turnaround for small orders, making it a go-to for urgent projects. In contrast, Provider F may require up to a week for fulfillment, which could pose challenges for those with tight deadlines.

-

Production Speed: Another critical factor is the production speed. Notably, 450mm or 600mm DTF printers operate at speeds that are 3-7 times faster than smaller machines, making them an efficient choice for expanding businesses that require quick turnaround times on larger orders.

By weighing these factors, marketing managers can effectively select a custom DTF provider that aligns with their operational needs, ensuring a thoughtful balance between cost, quality, and service speed. As one expert aptly noted, whether you press your own designs with top-quality supplies or rely on experienced providers, the power of custom DTF can elevate your custom apparel business to new heights. Additionally, for those contemplating greater control over production, establishing an in-house custom DTF operation can offer flexibility and potential long-term savings, albeit with higher initial investments.

This approach, while involving significant upfront costs, aligns with the findings from the case study on the cost of setting up an in-house DTF printing operation, which emphasizes the potential for greater profitability and adaptability in the long run.

Customization Options and Flexibility

Customization in custom dtf serves as a defining aspect of Direct-to-Film (DTF) transfers, allowing businesses to create unique visuals that resonate with their target audience. Leading providers understand that offering custom dtf customization options can make a significant difference in a competitive landscape. For instance, a single DTF printer has the capacity to produce all the fanwear sold at a 20,000-attendee sports game, showcasing the efficiency and potential of DTF printing.

The journey begins with the digital creation process, where logos, artwork, or any desired graphic are meticulously crafted using graphic software. These patterns are enhanced for particular substrates and printing specifications, ensuring high-quality results that address client needs. This optimization involves adjusting color profiles, resolution, and aesthetic elements to ensure compatibility with various materials, which is crucial for achieving the best print results.

Key areas of customization include:

-

Aesthetic Complexity: Some providers stand out by supporting intricate patterns and rich color gradients, while others may impose restrictions on pattern intricacy. As Dane Clement, president of Great Dane Graphics and vice president of creative for GroupeSTAHL, who has been involved in the decorated-apparel industry since 1987, states,

You'll get your prints fast and they'll always look great.

This emphasizes the importance of quality alongside complexity in custom dtf applications. -

Material Compatibility: The flexibility to print on various fabrics—ranging from cotton to polyester blends—is essential for businesses aiming to meet the diverse tastes of their clientele. This adaptability is gaining significance as market demand for unique clothing styles is anticipated to grow in 2024.

-

Size and Placement: Options for varying application sizes and positions on garments empower brands with greater creative freedom, allowing for tailored creations that resonate with individual buyer preferences.

Providers skilled in custom dtf customization aspects not only facilitate distinctive offerings but also foster deeper connections with their clients. Real-world examples of unique designs created through DTF technology showcase how these personalized touches can elevate a brand’s presence and appeal in a crowded marketplace.

Customer Support and Service Quality

When it comes to selecting a DTF transfer provider, the quality of assistance can be a game-changer. A responsive and helpful support team transforms the process into a smoother, more enjoyable experience. Key elements to consider include:

- Availability: Is support limited to business hours, or does the provider offer 24/7 assistance? This can be crucial for businesses needing immediate help.

- Communication Channels: The ease of reaching support through various options, like live chat, email, or phone, significantly enhances the experience, making it accessible and convenient.

- Problem Resolution: Assess how effectively the provider deals with issues such as order mistakes or shipping delays. Positive feedback regarding client support often reflects a provider’s dedication to service quality.

For instance, Faith Ellison recently stated, "Custom Laser Engraving provided me with excellent service and resolved my issue quickly," demonstrating how effective support can lead to satisfaction. Her experience highlights the importance of timely assistance. Furthermore, Clive Lawton remarked, "The quality of products and quick shipping from Custom Laser Engraving is impressive," emphasizing the positive aspects of their service.

Conversely, Robert Estrada shared a nightmare experience with another provider, stating, "I faced poor product quality and a complete lack of response," urging others to seek more reputable alternatives. Such differing experiences highlight the significance of prioritizing client assistance when investing in DTF prints. By concentrating on these elements, businesses can promote a seamless experience that cultivates greater satisfaction and loyalty among their clients.

Furthermore, it's essential to consider the operational efficiency of the processes, such as the pressing time of 15 seconds at 310 degrees for HOT PEEL, which not only impacts product quality but also enhances customer satisfaction through effective service delivery.

Future Trends in DTF Transfers

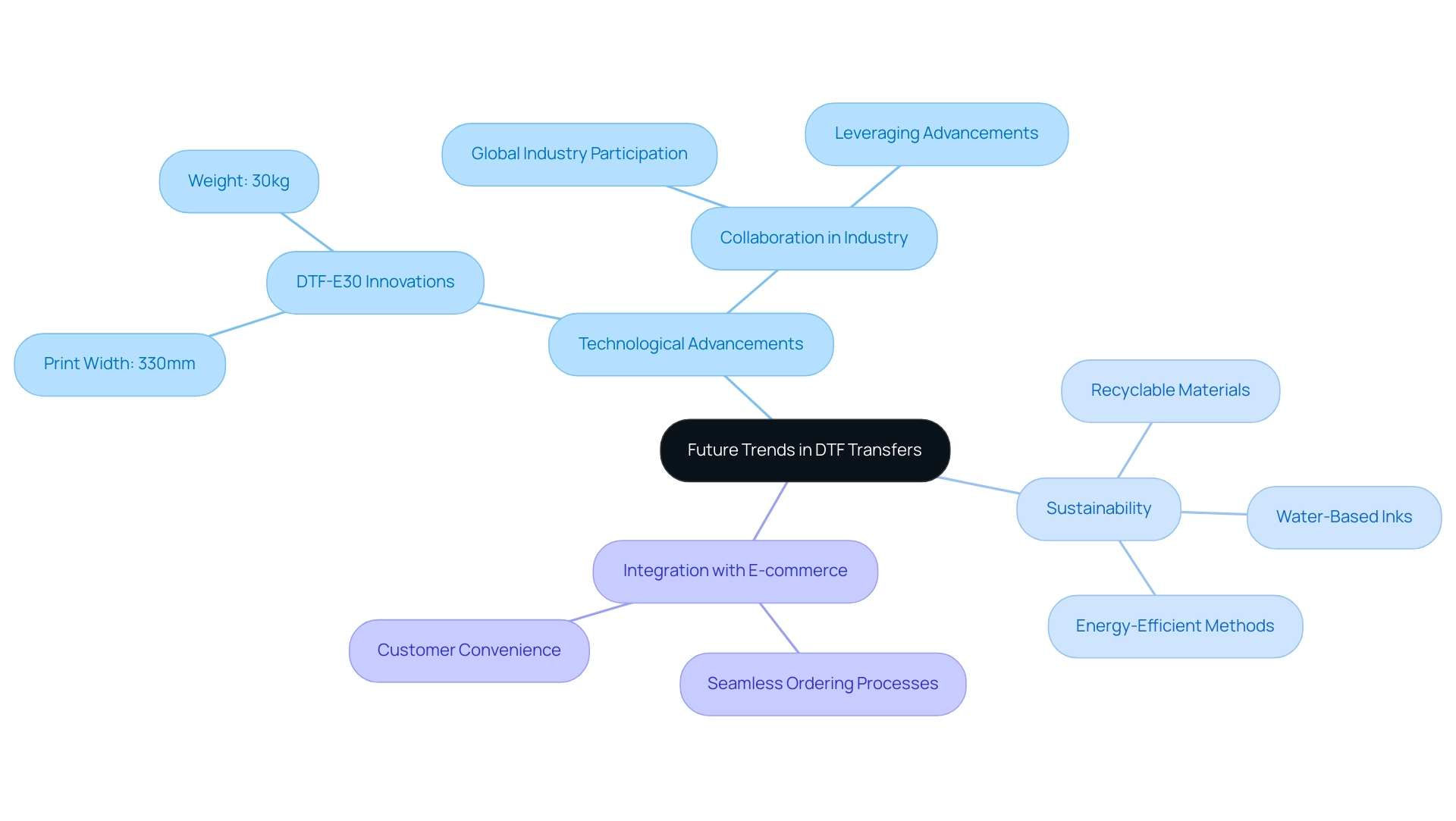

The custom printing environment is swiftly evolving, and several key trends are poised to reshape the future of DTF processes.

- Technological Advancements: Innovations like the DTF-E30, which boasts an impressive print width of 330mm and weighs in at 30kg, are paving the way for faster production and superior print quality. This enhanced capability allows businesses to increase their output while maintaining high standards.

As these technologies advance, they promise to make DTF applications even more appealing to a wider range of businesses. Allen Liu, the General Manager of Hanrun Paper, emphasizes that collaboration among global industry participants is essential to leverage these advancements effectively and ensure the successful growth of DTF technology.

-

Sustainability: As consumers increasingly prioritize eco-friendly options, DTF providers are expected to embrace sustainable practices. This shift might include the adoption of water-based inks, recyclable materials, and energy-efficient production methods, reflecting a broader commitment to environmental responsibility. By implementing these practices, companies can not only meet consumer demand but also contribute to a sustainable future.

-

Integration with E-commerce: With the surge in online shopping, DTF providers are likely to enhance their platforms to ensure seamless integration with e-commerce businesses. This development will facilitate smoother ordering processes and fulfillment, catering to the convenience that modern consumers expect.

Additionally, insights from case studies on maintaining UV printheads illustrate the importance of proper maintenance in prolonging the lifespan of printing technology, which is crucial as the industry moves towards more advanced DTF solutions. By keeping a pulse on these trends, businesses can strategically position themselves, harnessing the benefits of DTF transfers to effectively meet the evolving demands of their customers.

Conclusion

The world of Direct-to-Film (DTF) transfers is undeniably vibrant and full of potential for businesses and creators looking to make their mark in the custom printing landscape. This innovative technology not only simplifies the application of intricate and colorful designs but also empowers small businesses to meet the growing demand for personalized products. From understanding the nuances of DTF transfers to evaluating top providers based on pricing, quality, and turnaround times, marketers are equipped with the knowledge to make informed decisions that align with their operational needs.

Customization remains at the heart of DTF printing, allowing brands to connect with their audiences through unique designs. The flexibility in design complexity, material compatibility, and transfer placement positions DTF as a preferred solution for businesses eager to stand out in a crowded market. Furthermore, exceptional customer support can significantly enhance the overall experience, fostering loyalty and satisfaction among clients.

Looking ahead, the future of DTF transfers is bright, with technological advancements and sustainability initiatives poised to redefine the industry. As businesses adapt to these changes and integrate e-commerce solutions, they will not only improve operational efficiency but also cater to the evolving expectations of consumers. Embracing these trends will be essential for those seeking to thrive in this dynamic market and elevate their custom apparel offerings to new heights.